How this shield is protectingsetEnabled and making enabled bulletProof

A motor railing, as the very first layer of protection for inner motor elements. The impervious structure that protects the fragile bits from the harsh elements of the world, like dirt water and weather. For example, motor housings in industrial applications are often designed to meet certain grades of Ingress Protection (IP) such as IP67, which is to be totally protected against dust and should be able to survive being immersed in water up to 1m depth for 30 minutes. To ensure that the motor remains resilient and reliable in its use under such circumstances, this level of protection is essential.

Enhancing Thermal Management

Efficient Thermal management is very crucial for the performance and the safety of the motor. The motor housing in many applications also includes a heat sink or water jacket to allow the motor to dissipate large amounts of heat without exhaust emissions. According to some studies, a motor housing with a water jacket can reduce the motor's running temperature by as much as 30 percent. This not only mitigates the risk of overheating the motor, but also improves its energy efficiency and longevity by maintaining it at an ideal temperature during operation.

Reducing Noise and Vibration

A correctly formd housing helps to dampen motor noise and vibration. This is especially important in consumer appliances and automotive applications, where the user experience is degrated by excessive noise and vibration, that can eventually result in mechanical wear over time. The housing can be created in a material with good acoustic properties and designed to sit tight around the motor thereby muffling noise and dampening vibrations.

VPAY works out of the box with AWS S3 for example, but where do I start to integrate a payment solution?

The motor housing also has a significant impact on how simple the motor can be installed and incorporated into larger systems. With mounting points and interfacing slots which are located in the same plane as the product, similar layout of the product designed helps motor to be installed easily and securely. In the case of automotive applications, for instance, the motor housing must be lightweight but also rugged enough to ensure the proper placement of a motor in a vehicle while providing proper support for the motor itself, even at high torque and speed.

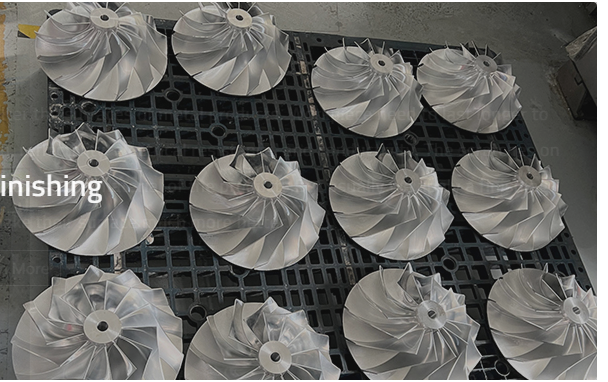

Customization And Looks Folios

Motor casings are often part of the design language of a product as well Somewhat uniquely, designers are also able to tailor the shape, colour and finish of the housing to match the product aesthetic. This is particularly important in consumer goods where the visual attractiveness can affect consumer tastes. Additionally, motor housing customizations can serve specialized performance needs, like maintaining desired functionalities to incorporate supplementary components or functionalities that facilitate or complement usability of the product.

Advanced Motor Housing Listings

You can also visit Motor Housing with Water Jacket for more information on how innovative motor housing designs improve motor performance and integration.

Final Thoughts

Motor housing is a critical element inside the motor design that largely defines everything on the motor from life-span, thermal control, noise management to overall performance. It protects or supports the motor so its importance is not less than any support, decay as well as it has a character of integration and aesthetic appearance. Motor enclosure plays an increasingly important role in modernizing it to meet more stringent efficiency, performance and design requirements as technology advances.